Call Us

86-755-82924037

Call Us

86-755-82924037Solar Valley calcium fluoride lenses undergo a meticulous fabrication process, utilizing state-of-the-art multi-axis free-form surface machining equipment. This includes fine grinding, precise measurements, and ultra-precision polishing, all conducted under strict control of both the machinery and the processing environment. The aim is to achieve unparalleled precision in the optical aspheric domain. Advanced correction polishing techniques are applied to refine this CaF2 lens surface, achieving an optical aspherical surface shape accuracy of ≤0.1 micron and a surface roughness of Ra≤0.01 micron, characteristic of high-quality infrared barium fluoride lenses.

| Calcium Fluoride Lenses product parameter table | |||

| Project | Indicator requirements | ||

| 1. Material | Calcium Fluoride materials | ||

| 2. Diameter | OD≤φ150mm OD±0.025 or according to customer requirements | ||

| 3. Center thickness | T±0.01 or according to customer requirements | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Effective aperture | ED>80% aspheric area | ||

| 7. Coating | AR coating R<0.5% @λnm | ||

| 8. Surface shape | Ultra-high precision Rt≤0.1μm, high precision Rt≤0.5μm, precision Rt≤1μm | ||

| 9. Surface quality | 60-40, 40-20, 20-10 | ||

Calcium Fluoride (CaF2) lenses are employed in a variety of applications, including spectroscopic windows, lenses, and cryogenically cooled thermal imaging systems. These CaF2 lenses are particularly effective for a broad spectrum of Ultraviolet (UV), Visible, and Infrared (IR) applications due to their low absorption and high damage threshold, making them ideal for use with Excimer lasers. The low refractive index of Calcium Fluoride also eliminates the need for anti-reflection coatings.

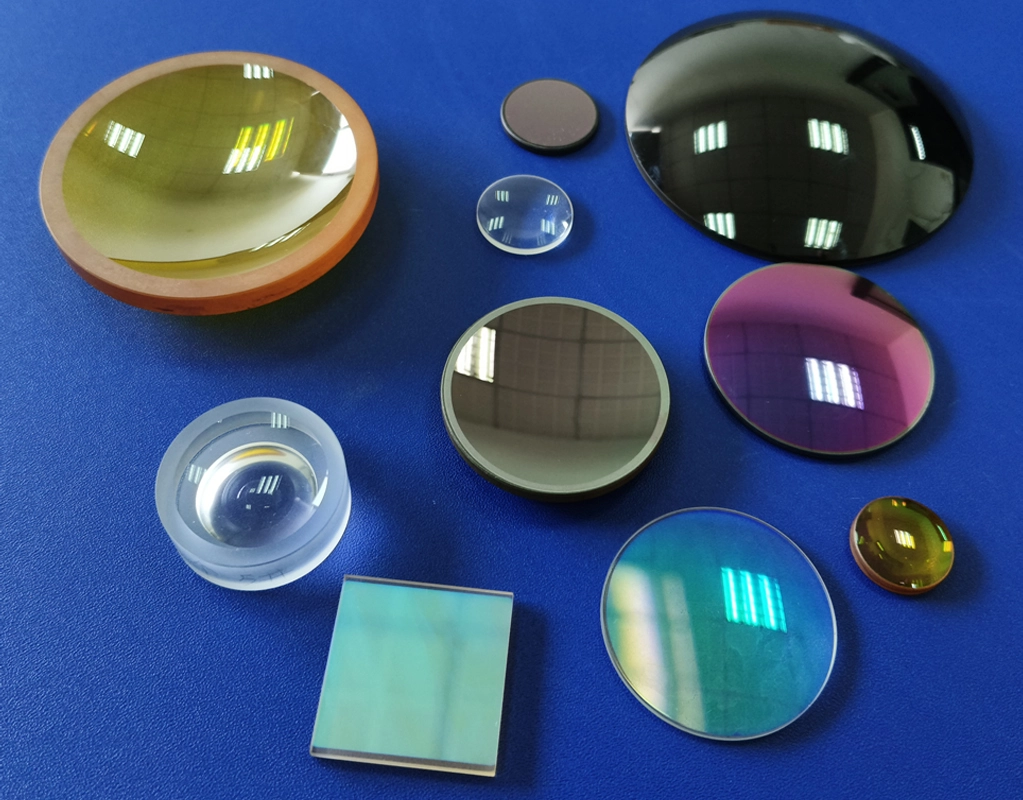

One-stop customized production: Solar Valley can process a variety of infrared lenses, flat convex, double convex, convex and concave structure aspherical Calcium fluoride.The shape can be round, D-type, square and so on.

Material: CaF2 has a high transmittance through 0.18-8.0 microns, which is used for high transmittance applications in ultraviolet and infrared spectra. CaF2 lens is also widely used in excimer laser environment because of its excellent laser power damage threshold. CaF2 has a low dispersion and refractive index, ranging from 180nm to 8.0 microns, from 1.35 to 1.51

Lens performance: Calcium fluoride (CaF2) crystal, high hardness, strong resistance to mechanical shock and thermal shock, in the ultraviolet, visible and infrared field has a good transmittance, used in laser, infrared optics, ultraviolet optics and detectors and other scientific and technological fields, suitable for strict requirements, need UV to mid-wave infrared spectral performance of the application, calcium fluoride flat lenticular with low refractive index, High laser damage thresholds and low coaxial and radial stress birefringence make them ideal for use with excimer lasers or for integration into infrared systems.

Product indicators:

1. Maximum outer dimension of circular calcium fluoride lens: OD≤φ150mm

2. The maximum external dimension of square calcium fluoride lens: L×W ≤100×100mm

3. Calcium fluoride lens can reach the following accuracy levels according to customer requirements:

Ultra-high precision: surface shape error < 0.1μm, surface roughness < 0.01μm

High precision grade: Surface error < 0.5μm, surface roughness < 0.05μm Precision grade: Surface error < 1μm, surface roughness < 0.1μm

Similar product of GaAs focus lens is also provided for you to explore.

Surface defect grade: 60-40, 40-20, 20-10 according to customer requirements.

Coating: According to customer requirements for coating, can provide no coating or a variety of broadband anti-reflection coating options.