Call Us

86-755-82924037

Call Us

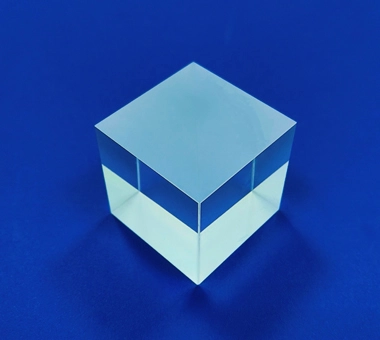

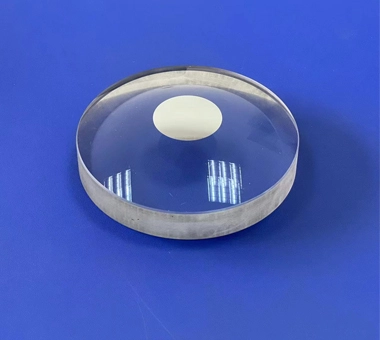

86-755-82924037Silicon lenses are produced through a sophisticated manufacturing process utilizing state-of-the-art single-point diamond ultra-precision multi-axis free-form surface processing technology. This comprehensive procedure includes steps such as ultra-high-precision single-point turning, meticulous grinding, accurate measuring, and advanced polishing. The entire production process is subject to rigorous control, ensuring both the machinery and the environmental conditions are optimized to achieve the highest level of precision in the aspheric optical domain. By employing innovative correction polishing technology, the surface of the lenses is significantly improved. As a result, these silicon lenses feature exceptional infrared aspheric quality, with an optical aspheric surface shape accuracy of ≤0.1 micron and a surface roughness of Ra ≤0.01 micron. This meticulous attention to detail and precision engineering establishes silicon lenses as a benchmark for optical component excellence.

| Silicon lens product parameter table | |||

| project | Indicator requirements | ||

| 1. Material | Monocrystalline silicon material. | ||

| 2. Diameter | OD±0.025 or as per customer requirements | ||

| 3. Center thickness | T±0.01 or according to customer requirements | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Effective aperture | ED>80% aspheric area | ||

| 7. Coating | AR or DLC coating R<0.5% @λnm | ||

| 8. Surface shape | Ultra-high precision Rt≤0.1μm, high precision Rt≤0.5μm, precision Rt≤1μm | ||

| 9.Surface quality | 60-40, 40-20, 20-10 | ||

One-stop customized production: Solar Valley processes various infrared lenses, plano-convex, biconvex, and convex-concave structure aspheric silicon lenses according to customer requirements. The shape of the silicon lens can be circular, D-shaped, square, trapezoidal, etc.

Material: Monocrystalline silicon is an infrared material with excellent comprehensive cost properties and can be divided into Transmissive Grade and Reflective Grade. As a transmission-grade material, optical-grade Czochralski silicon (OCZ-Si) is widely used in the mid-infrared (1-6um) band, with an infrared transmittance of over 50%. Zone melting monocrystalline silicon can be used in a wider band (1-14um), and high-purity zone melting monocrystalline silicon (HPFZ-Si) can even be used in the far-infrared band (greater than 30um).

Lens properties: used for collimation or focusing applications, with uniform light spot, clear projection, complete specifications, and aerospace quality.

Product indicator description:

1. Maximum dimensions of circular infrared aspheric lens: OD≤φ300mm

2. Maximum dimensions of square infrared aspheric lens: L×W ≤200×200mm

3. Infrared aspherical lenses can reach the following accuracy levels according to customer requirements:

Ultra-high precision grade: surface error <0.1μm, surface roughness <0.01μm

High precision grade: Surface error <0.5μm, surface roughness <0.05μm Precision grade: Surface error <1μm, surface roughness <0.1μm

Similar product of gallium arsenide lens is also provided for you to explore.

Surface defect grade: 60-40, 40-20, 20-10. Produced according to customer requirements.

Coating: Coating according to customer requirements.