Call Us

86-755-82924037

Call Us

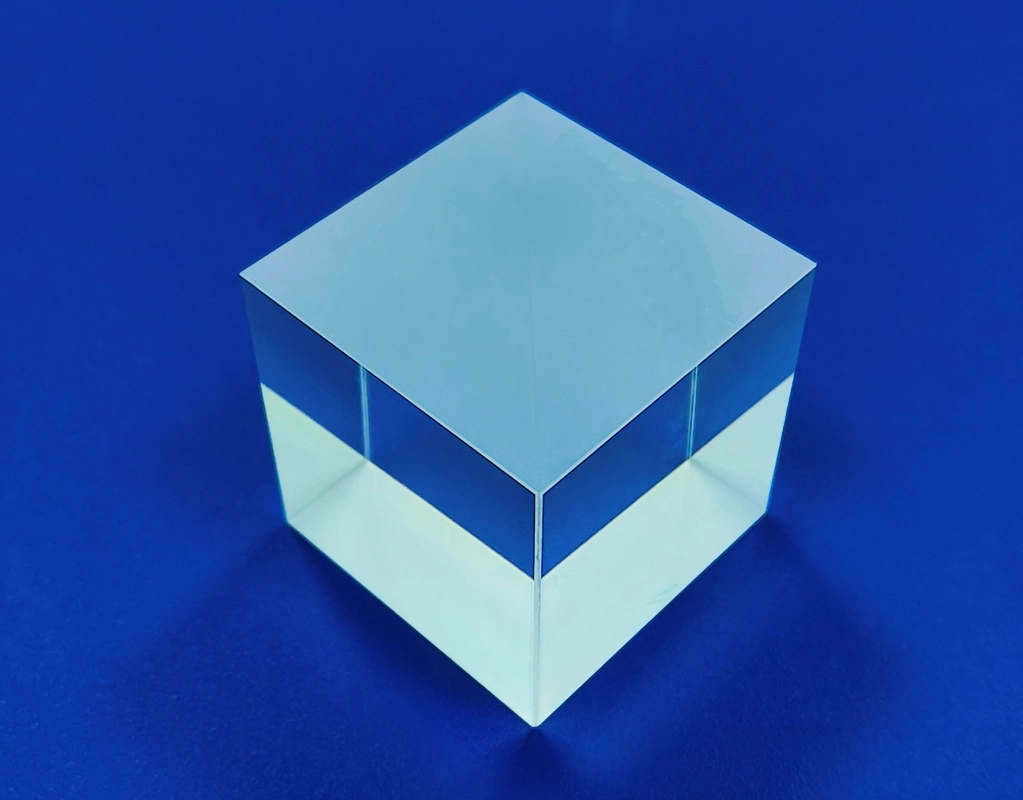

86-755-82924037The cemented Prism Cube is used in the optical system. In order to reduce the volume of the prism under a certain light aperture, two right-angle prisms of the same size and material can be cemented together along the inclined plane to form a cubic prism. It is mainly used in cameras, projectors, periscopes, and telescopes. After milling, fine grinding, grinding, and polishing, the right-angle prism in the cemented prism can achieve the optical surface accuracy ≤0.1 micron and the surface roughness Ra≤0.01 micron. Two right-angle prisms are cemented, and a prism cube is formed by performing precision gluing and eccentricity tests using a centering device with a UV photosensitive adhesive curing device. The optic prism cube is essential in various optical applications, and the optical glass prism cube ensures high precision and durability. These cube prisms are often referred to as glass cube prisms in the industry.

| Cemented Prism Cubes parameter table | |||

| Project | Indicator requirements | ||

| 1. Material | Use a variety of high-low refractive index optical glass, optical quartz | ||

| 2. Overall dimensions | Square L×W≤150×150mm ±0.05mm | ||

| 3. Thickness | T≤100mm±0.02 according to customer requirements | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Design wavelength | according to customers needs | ||

| 7. Coating | Coating R<0.5% @λnm according to customer requirements | ||

| 8. Eccentricity | ≤2′ | ||

| 9. Effective aperture | ED>95% aspheric area | ||

| 10. Surface shape | Ultra-high precision Rt≤0.1μm, high-precision Rt≤0.5μm, precision Rt≤1μm | ||

| 11. Surface quality | 60-40、40-20、20-10 | ||

The maximum external dimension of the cemented optic prism cube: L×W≤150×150mm.

The center thickness of the cemented glass cube prism: T≤100mm.

Cemented optical glass prism cubes can achieve the following accuracy levels according to customer requirements:

Ultra-high precision: surface shape error < 0.1μm, surface roughness < 0.01μm.

High precision grade: Surface error < 0.5μm, surface roughness < 0.05μm.

Precision grade: Surface error < 1μm, surface roughness < 0.1μm.

Surface defect grade: 60-40, 40-20, 20-10, according to customer requirements.

Coating: can be coated on three sides, one side coated with matting paint, according to customer requirements for coating.

One-stop customized production: Solar Valley optical prism manufacturer processes cemented prism cubes of various sizes and structures according to customer requirements.

Material: our optic prism cube uses a variety of high-low refractive index optical glass, optical quartz.

Cube performance of cemented prism: cemented cube prisms are plated with anti-reflection multilayer film on the incident surface and the exit surface, because the film layer has almost no absorption, the loss of incident light is very small, and the optical axis shift and ginning phenomenon are almost no. Tianyang Valley strictly matches the size and center thickness to ensure the adhesive thickness and accurate center thickness control to meet the high precision requirements. Using UV curing/gluing technology on different glass materials, Tianyang Valley dynamically adjusts the center of the optical axis of the two parts during the gluing process to eliminate the overall optical axis deviation after gluing. For high refractive index optical materials, the use of high refractive index UV photosensitive adhesive corresponding, accurate control of the center thickness tolerance of the adhesive can be used for optical design that is very sensitive to air spacing.