Call Us

86-755-82924037

Call Us

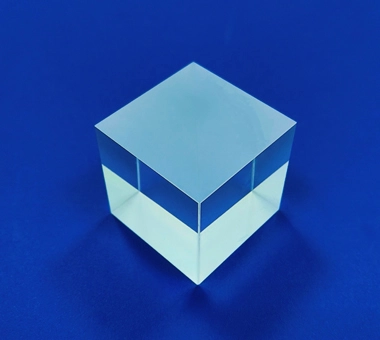

86-755-82924037Dielectric HR mirror is a kind of reflective mirror, and the reflective film can be a metal reflective film or a total dielectric reflective film. The dielectric reflective film uses the principle of multi-beam interference to significantly improve the reflectivity of light at the air-glass interface. By alternately coating high and low refractive index multi-layer films on the surface of the lens, the combined amplitude of reflected light can be increased, and the reflectivity of the reflective film can reach over 99.9% of the specially optimized design. The reflectivity of the reflective metal film is only 97%. The processing technology of Tianyanggu dielectric HR mirrors is mature and it is easy to achieve high-precision dimensions. The accuracy of prisms with a size of less than 3 inches can be controlled within 3 seconds. The dielectric HR mirror has been milled, finely ground, ground, polished, and coated to achieve high-precision mirror flatness, precise angles, and optical performance.

| Media HR mirror product parameter table | ||

| project | Indicator requirements | |

| 1. Material | Use optical glass, fused quartz and other materials | |

| 2. Overall dimensions | Maximum overall size: ≤150×150mm ±0.05mm according to customer requirements | |

| 3. Thickness | T≤50mm±0.02 according to customer requirements | |

| 6. Working wavelength | In the ultraviolet (UV), visible or infrared (IR) spectrum | |

| 8. Coating | UV/VIS dielectric coating is coated according to customer requirements | |

| 9. Angle tolerance | 3′ | |

| 10. Effective aperture | ED>95% area | |

| 11. Flatness | λ/10 @632.8 nm | |

| 12. Surface quality | 60-40, 40-20, 20-10 | |

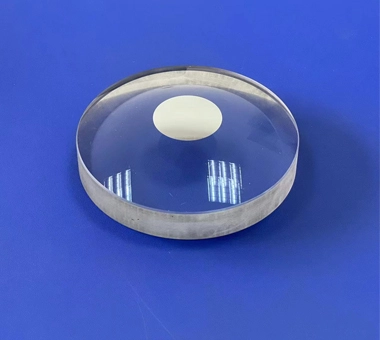

One-stop customized production: Solar Valley processes dielectric HR mirrors of various shapes and structures according to customer requirements, such as circles, squares, trapezoids, etc.

Material: The base material uses optical glass, fused quartz and other materials.

Dielectric HR mirror properties: Tianyanggu dielectric HR mirror achieves the best performance in the ultraviolet (UV), visible light or infrared (IR) spectrum. The stability and wear resistance of the dielectric reflective film in the air are better than those of metal films. The use of LEGB borosilicate or equivalent ensures that the mirror has low thermal expansion coefficient properties. Dielectric HR mirrors are used in demanding beam control and reflection applications such as imaging and astronomy.

Description of product size indicators: Maximum dimensions of media HR mirror: ≤150×150mm Thickness T≤50mm

Surface defect level: 60-40, 40-20, 20-10 Produced according to customer requirements.

Coating: UV/VIS dielectric coating is coated according to customer requirements.